Description

|

Laser source |

JPT pulse fiber laser |

| Laser power | 50W/100W |

| Power supply | Single-phase 220V±10%, 50/60Hz AC |

| Machine power comsumption | 2500W (width water chiller) |

| Setting up environment | Flat, no vibration, no impact |

|

Working temperature |

0℃-40℃ |

| Working humidity | ≤80% |

| Average laser power | ≥200W |

| Power range (℅) | 10-100 (adjustment) |

|

Repeat frequency (KHz) |

10-50 (adjustment) |

| Cleaning efficiency (㎡/h) | 12 |

| Focal length (mm) | 210-160 (changeable) |

| Cooling mode | Air cooling |

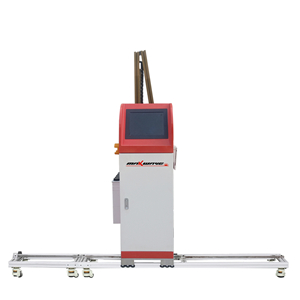

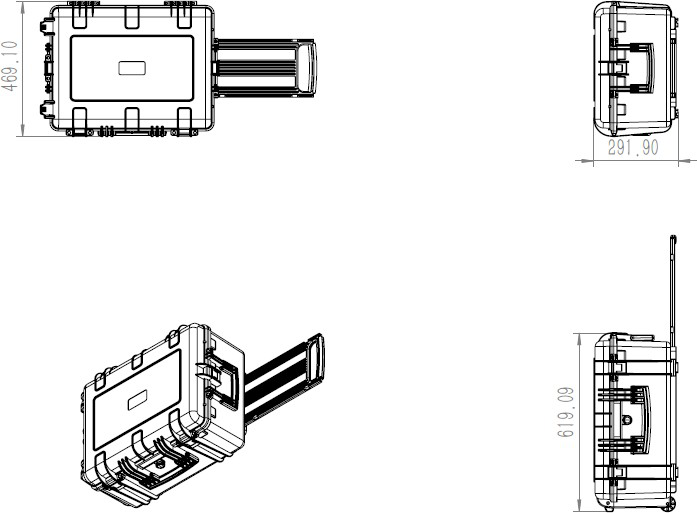

| Size | 750mm*600mm*500mm |

| Weight | 37KG/48KG |

| Scanning width | 10-80mm |

| Mobile mode | Handheld |

1. Non-contact cleaning, does not damage the part base

2. Standard cleaning, accurate position, precise size, selective cleaning

3. No chemical cleaning solution, no consumables, safety and environmental protection

4. High cleanliness and save time

5. Laser cleaning system is stable

1. No damage to the base of the material due to the no-touch surface cleaning performance.

2. Precise cleaning technic for the specific area in a selected area.

3. No need of chemistry or other added supplies.

4. Easy to be operated, can be hand-held or auto-cleaned by installing a robotic arm.

5. Small cleaning time consumption and comes with a high quality finishing result.

6. Stable and impacted integrated design which results to no extra maintenance.

1. Core technology. When we were a small factory, we have focused on the development of core components such as laser power supplies and optical path. Unlike other suppliers, they only sell through assembly equipment.

2. Independent research and development department. This means we can offer our customers customized machines and improve the equipment according to market changes

3. Dealer support plan. In the early stage of customers' market development, we provide technical parameters for the installation and use of equipment free of charge, share good marketing methods, help customers win the market and achieve success.

4. Strict testing. All of the suppliers we work with come from world-class manufacturers. Before the delivery, each machine needs to be tested and inspected for 48 hours (marking machine, welding machine) and 4-7 days (cutting machine) to ensure quality and safety.

5. Timely delivery. Each machine has an accurate assembly process and strict time control to ensure that customers receive goods in a timely manner.

6. After-sales service and guarantee. We offer a 2-year warranty and any problems occur during the period and we have a responsibility to resolve them. If any part of the machine is broken, we will repair it for free and send free accessories.