Fiber laser welding machine is popular after price decreasing

fiber Laser welding machine on gears welding industry

Nowadays gears are widely used in automotive manufacturing, medical equipment, machinery manufacturing, aerospace and other fields. And the welding process of the gear directly affects the performance of the product. The traditional welding process has the disadvantages of high heat input and easy deformation. So it cannot meet the high precision requirements of the gear. For now both vacuum electron beam welding and laser welding can meet the requirements of gear welding process. However, vacuum electron beam welding requires a vacuum environment. and it is with low efficiency, expensive equipment. Therefore it is not suitable for industrial production. Therefore, laser welding is more suitable for gear welding and laser welding technology has become an important condition for gear welding applications.

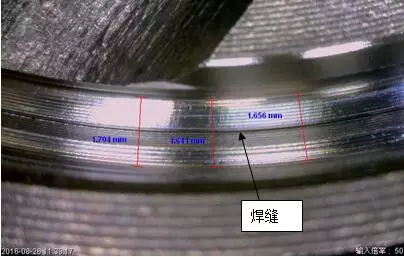

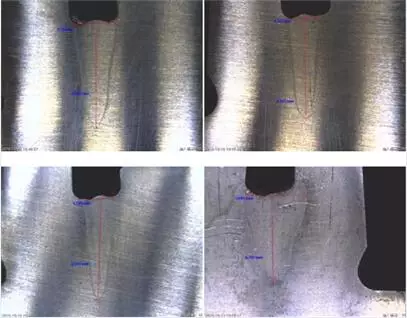

After the high energy density spot of the fiber laser acts on the surface of the material, we can obtain a large aspect ratio (ratio of weld penetration to melt width). Through proper process adjustment, the amount of deformation of the gear after welding is small and no need subsequent processing. The laser welding assembly clearance requirement is one of the main reasons for limiting its application. And the gear assembly is an interference fit. So the clearance fit requirement during the welding process is basically negligible.

Gear assembly form

The fiber laser is for the welding test and the gears were pre-welded. And different welding speeds can receive the different weld penetration and melt width. It can be seen from the figure that the weld seam is obviously “nail shape”. Meanwhile there is no obvious welding heat affected zone. And the weld seam has no defects such as pores and cracks. Fiber laser welding can meet most gear welding process requirements.

Gear assembly form

Fiber laser welding has the characteristics of fast welding speed, small deformation after welding and no post-weld treatment. Now it is very popular in various industries of the national economy. China fiber laser is now specializing in fiber laser research and development and production. What’s more, provides customers with a wide range of application process technology support. So to provide customers with high-quality fiber lasers is the driving force behind the continuous efforts and progress of the company.

If you have any more information,feel free to contact me:

Richard from Maxwave LASER

WhatsApp&Wechat&Mobile: +86 18571639620

Skype:richard12677